- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

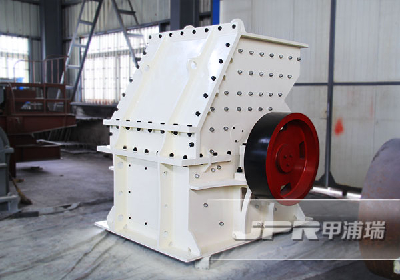

- Place of Origin: SHANGHAI

- Brand Name: JPR

- Model Number: HGM

Product introduction

The JPR Micro Micro Powder Grinding Mill Grinding Mill(ultrafine mill) is for super-fine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 6 percent such as kaolin, limestone, calcite, marble, talcum, barite, gypsum, dolomite, bentonite mud, mica, pyrophyllite, sepiolite, diatomite, graphite, alunite, fluorite, potassium feldspar, phosphorite, pigment and so on. The granularity of the end products is 325-2500 meshes.

Performance features

1. Higher output. Its output increases by 10%-20% comparing with Raymond mill under the same power condition.

2. Larger range of final fineness. Size of final product can be 0.613mm (30mesh) –0.033mm (425mesh). Some can reach the fineness of 0.013mm (1000 mesh).

3. Good dust control. High Pressure Suspension Mill meets the requirement of national dust-dump standard.

4. Easy to operate. The whole system is combined by some independent systems, and the cohesion between the systems is good.

5. Excellent sealing. The multi-class seals are adopted to keep the grinding equipment tight closed.

Working principle

General: Crushing -- Grinding -- Selecting -- Collecting

Materials first enter jaw crusher to be crushed to smaller size. Then they are lift to storage room by elevator. Vibrating feeder will feed materials into micro powder grinding mill chamber evenly and gradually. After being grinded, the powder will be blowed to cyclone by blower.

Then the material will be transferred to storage room through pipes, and then will be discharged as final products. The whole processof micro powder grinding mill works in a negative pressure environment. First, through pipes, the air from the blower enters the cyclone collector above the storage room along with powder, and then returns to the blower through return pipe. In the way, air can be recycled.

There is a powder locking equipment under the cyclone in micro powder grinding mill , which isolates the outside positive air pressure and the negative air pressure inside cyclone. And this ensures high productivity.

In addition, the residual air and dust under the main unit will be transferred to dust catcher equipment through pipes and be cleaned there. The clean air will be discharged so that environment will be protected.

- Place of Origin: SHANGHAI

- Brand Name: JPR

- Model Number: HGM

Technical parameters

| Model | HGM80 | HGM90 | HGM100L | HGM100L-Ⅰ | HGM125 | HGM168 |

| Ring Diameter(mm) | 800 | 930 | 1035 | 1035 | 1300 | 1680 |

| Ring NO.(layer) | 3 | 4 | 4 | 4 | 4 | 4 |

| Roller NO.(piece) | 21 | 29 | 28 | 28 | 32 | 44 |

| Main Shaft speed(r.p.min) | 230-240 | 200-220 | 180-200 | 180-200 | 135-155 | 120-130 |

| Input Size(mm) | ≦10 | ≦10 | ≦15 | ≦15 | ≦20 | ≦25 |

| Finished Size(mesh) | 325~2500 | 325~2500 | 325~2500 | 325~2500 | 325~2000 | 150~1500 |

| Capacity(t/h) | 0.5-4.5 | 0.8-6.5 | 1-8.5 | 1.5-9 | 2.5-15 | 5-45 |

| Overall Dimension(L*W*H, m) | 13.9×4×6.2 | 14.7×4.8×7.2 | 18×4.6×8.6 | 18×4.6×8.6 | 14×9×10.25 | 26.3×7.5×11.9 |

| Motor power(kW) | 123-143 | 168.35 | 243.95 | 243.95 | 341.3 | 603 |